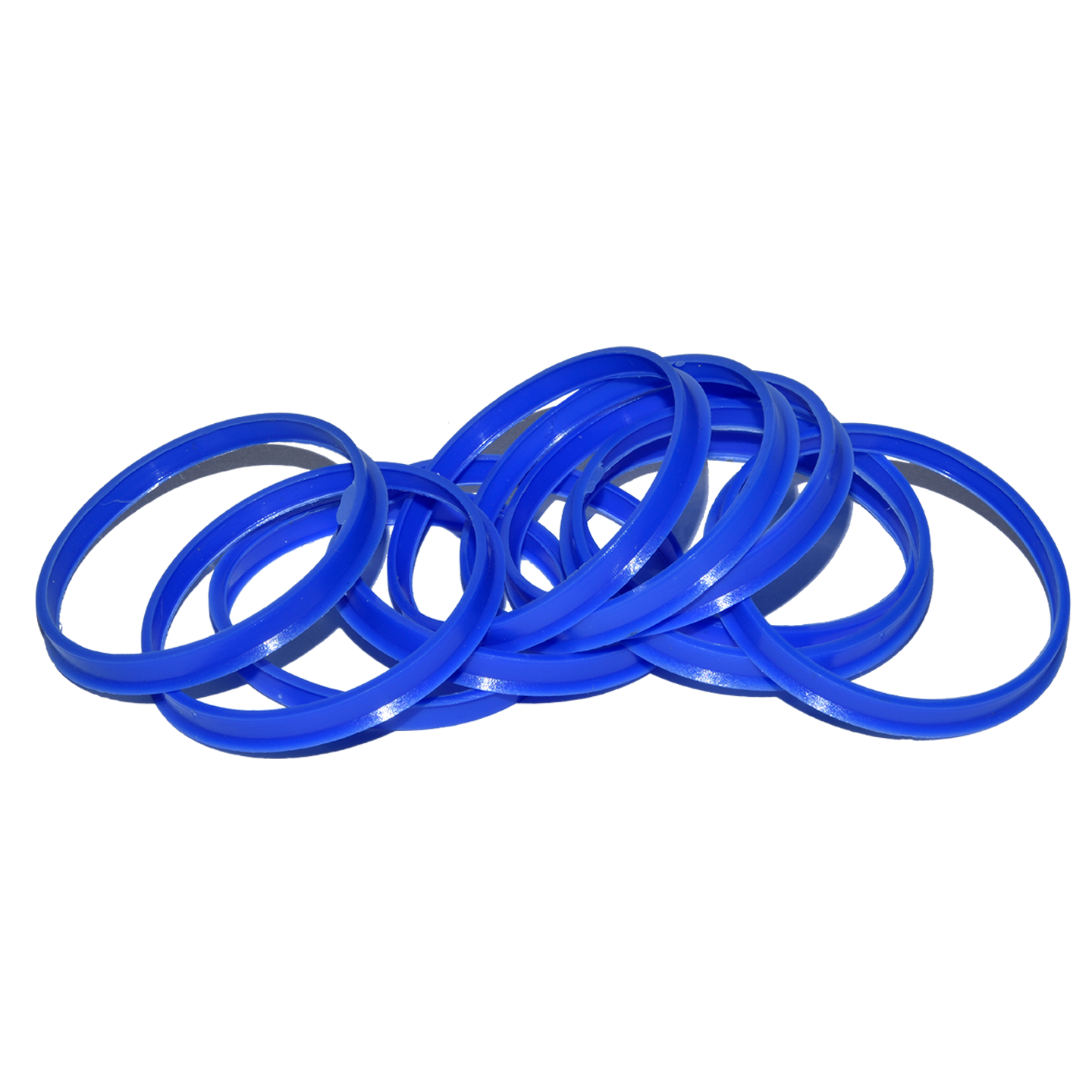

Borosil Laboratory bottles are chemically resistant and stable. When fitted with a plastic pouring ring dripping can be totally eliminated. As there is only one size of screw thread for all bottles from 100 ml onwards, the screw caps and pouring rings are fully interchangeable. The bottles, pouring rings and caps are autoclavable and sterilizable.

Properties :

Light protection :

• Amber bottles : Protects media from light radiation with a wave-length between 300 nm and 500 nm

Safe closure ensures storage of products such as

• Dairy products

• Serums

High resistance to thermal shock (up to 140C)

HANDLING :

Sterilization :

Bottles can be steam sterilized after washing. Following are recommendation and guidelines.

• Soiled bottle must be cleaned first, otherwise microorganism cannot be effectively destroyed and chemicals adhering to surface can damage it as a result of high temperature involved.

• To prevent pressure build in bottle, the screw cap should be left loose on the bottle neck (one turn maximum). It should not be closed tight as the pressure built up at higher temperatures should be released to prevent the bottle from breakage.

• Ensure that saturated steam is used and that it has unhindered access to all contaminated places. This is the only way to achieve effective steam sterilization.

Thawing frozen substances :

The frozen material can be thawed by immersing the bottle in liquid bath taking care that the temperature difference does not exceed 100 degree C. This will ensure that the frozen material is heated uniformly from all sides without damaging the bottle. It can however also be thawed slowly so that the surface melts first, allowing the material to expand.

Freezing substances

Recommendation: When freezing, always place the bottles at an angle approx. 45C and do not fill to more than capacity (to increase surface area). Temperature limit - 40C as the plastic caps and pouring ring do not withstand lower temperatures.

Free Shipping on Orders over $200.00

*Excludes Rural Addresses

Email: sales@interlab.co.nz

Call us: +64 4 972 2330

Free Shipping on Orders over $200.00

*Excludes Rural Addresses