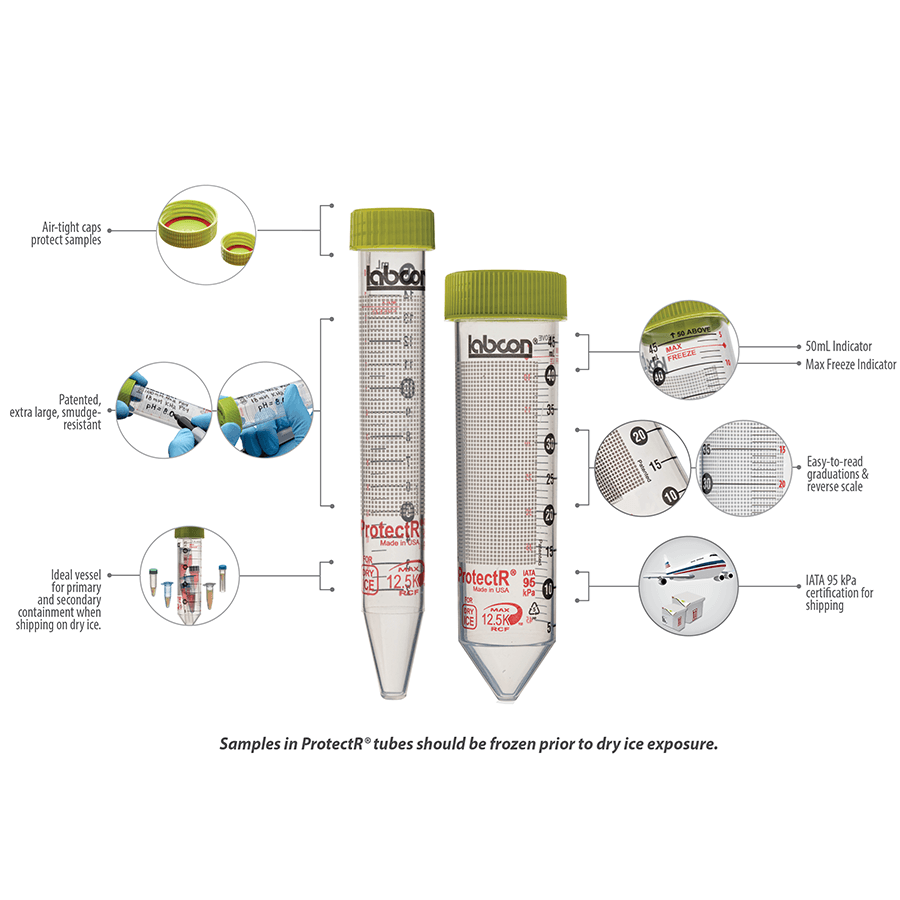

Centrifuge Tube. ProtectR. IntegraPack Sterile

Available on Backorder

Product Enquiry

ProtectR Tubes Sterile – 50/pk

- Protects Samples Shipped On Dry Ice,

- Keeps pH Stable,

- CO2 Resistant

- Certified For Shipping

- Autoclavable

- Freezable to -80° (Samples in CO2 Resistant Tubes should be frozen prior to dry ice exposure.)

- Low trace metals

- RNase & DNase Free

5 × 10 per gamma sterile pack (50pcs total)

Samples of proteins, other biological molecules, and cell cultures are commonly shipped and stored on dry ice, putting them at risk of acidification by up to 2.5 pH units. In standard centrifuge tubes, CO2 vapor from dry ice enters the tube headspace and causes a significant drop in the pH of the sample. Even in short term storage conditions, samples may become acidified. This acidification can affect the integrity and reproducibility of samples, and may result in a loss of protein activity.

Protect samples from acidification

Other container closure systems do not provide a reliable barrier against CO2 sublimating from dry ice. Carbonic acid formation will cause a decrease in pH by as much as 2.5 pH units. In this experiment, acidification is seen as a solution’s color shift from blue to yellow.

EXPERIMENT:

Pre-Frozen* tubes of buffered pH 8.0 solution were placed on dry ice for 48 hours.

RESULTS:

Carbon dioxide enters Other Tubes headspace and acidification expands through the protein solution.

FINDINGS:

Only the ProtectR Tube protected the solution from acidification.

Samples in CO2 Resistant Tubes should be frozen prior to dry ice exposure.

The ideal shipping tube for small and large sample volumes

ProtectR® tubes are the ideal vessel for primary and secondary sample containment. Samples are shipped on dry ice in a variety of volumes. When shipped in standard, small volume tubes, samples are at risk of acidification. ProtectR® tubes can be used as a secondary shipping tube for multiple small volume tubes. With their airtight, leak-resistant secure seal, ProtectR® tubes provide a protective barrier against CO2 exposure, safeguarding the sample(s) inside from costly damage. Only ProtectR® tubes ensure consistent sample integrity and protein activity across experiments. Even if samples are delayed during shipping, they will not become compromised, saving time and money.

IATA 95 kPa certified for shipping

Most international and domestic carriers now require adherence to the IATA standards for all biological substance shipments. IATA 95 kPa certification ensures containers are leak-resistant under differential pressure conditions such as in air transport. This certification requires containers to prove capable of withstanding, without leakage, an internal pressure producing a pressure differential of not less than 95 kPa (0.95 bar, 13.8 psi).

Since air transportation is typically the most rigorous transport condition, containers that meet IATA regulations will also meet the requirements of other transport methods.

| Weight | N/A |

|---|---|

| Sterile | Yes |

| Volume | 15ml, 50ml |

Related products

- In StockSKU: 3830-325-CLEARANCE

- In StockSKU: 3210-325 - CLEARANCE